top of page

Automated Labeling System

This section features images and a video documenting our team's development process for an automated labeling prototype, designed to enhance a company’s repackaging workflow. We engineered a cost-effective, Arduino-controlled system that utilizes infrared sensors for product detection and stepper motors for precise label application. The solution was built to reduce manual labor, minimize labeling errors, and significantly improve operational speed and consistency.

*Credits: Prof. Kenichi Kato, Prof. Ang Chee Khian, Mr. Gary Lee Ngee Howe

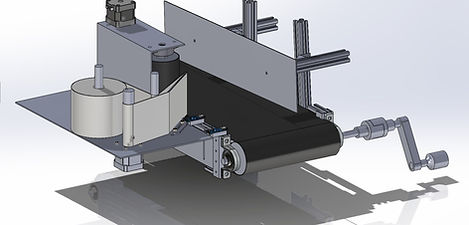

Concept Design Diagram

This 3D model illustrates our proposed automated labeling system, featuring a conveyor belt with an adjustable guide rail for consistent product alignment, a precision label roller for accurate application, and a feeder-rewinder mechanism for efficient label strip management.

Skills Utilized:

- SolidWorks

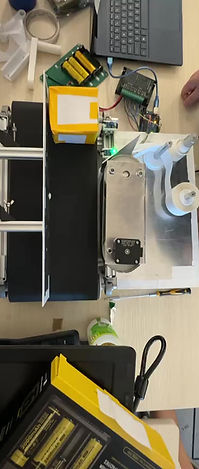

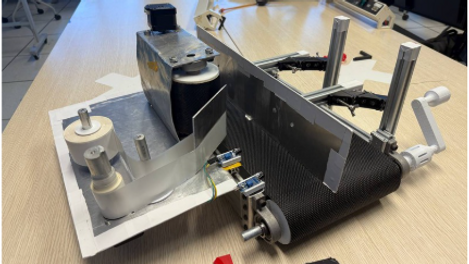

Fabricating the Prototype

This image showcases the final iteration of our prototype. The system integrates a label roller, infrared sensor, and motorized components within a compact frame to simulate real-world logistics operations. This systems primary functions are accurate product detection, synchronized label application, and reliable mechanical coordination.

Skills Utilized:

- Python Programming

- Metalwork Fabrication

Final Prototype Demonstration Video

The video features our mini-scale automated labeling system prototype in action, detecting the product and applying a label with precision.

It highlights the coordinated operation of the IR sensor, Arduino-based control logic, and a motorized roller mechanism, effectively simulating a real-world labeling workflow within a compact and efficient setup.

bottom of page